The F-35 Integrated Assembly Line in Palmdale, California, must run efficiently, with safety and quality top-of-mind.

Breaking Silos

ASTAR is transforming Northrop Grumman's engineer training on the production floor.

By Julie Knight

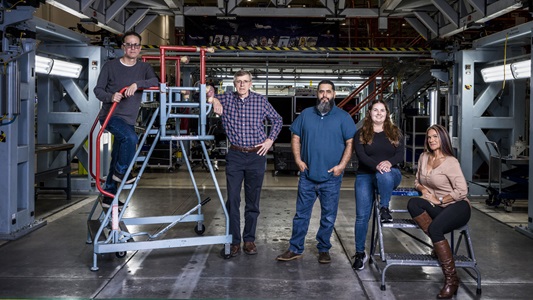

Northrop Grumman production operations employees in Palmdale, California often begin their journey at Aeronautics Systems Training for Advanced Refinement, or ASTAR, to gain hands-on experience before working on production floors like the F-35 center fuselage Integrated Assembly Line (IAL).

The F-35 program engineering team saw an opportunity: leverage ASTAR curriculum to provide hands-on training to early-career engineers. The ASTAR Engineering pilot program was a first for Northrop Grumman, creating a full-cycle training environment to design, produce and assemble parts using tools and processes from real production environments.

The program brings together engineers from disciplines that rarely get the opportunity to collaborate — design, development, manufacturing, testing — and gives them an opportunity to train side-by-side and on the production floor.

Speeding Up Training: From Years to Hours

ASTAR Engineering trainees gain more than skills and confidence in their work.

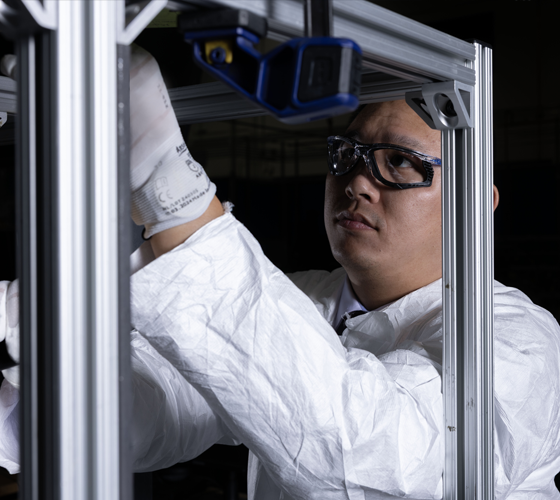

“In just 40 hours, trainees get an inside view of our manufacturing processes that could otherwise take years to witness or experience,” said Kevin Luu, an F-35 aeronautical engineer.

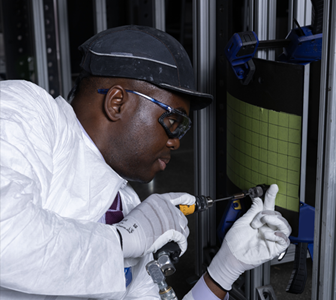

Chrys Koomson, ASTAR Engineering manager, added that the new program helps engineers better understand how their engineering designs translate into a technician’s day-to-day tasks.

“As engineers, we did not always understand some of the challenges our techs faced on the line,” Chrys said. “By putting ourselves in their shoes, we stopped asking why and started understanding how we could improve production processes.”

Training together across disciplines makes it easier to collaborate and achieve better results.

Theory Meets Reality

The ASTAR engineering program has delivered hands-on training to over 250 trainees from multiple disciplines and programs, including high school and college interns and full-time Northrop Grumman engineers at the Palmdale and El Segundo sites.

For many engineers, ASTAR training fills critical gaps left by remote learning.

Channe Asuncion, now an engineer on the F-35 program, interned at Northrop Grumman in 2023 before engineers started participating in ASTAR training.

“I wish I’d had ASTAR training as an intern,” said Channe. “When I started working here full-time, I’d never even picked up a drill because all my college classes were online, but I was expected to tell technicians how to do their job. ASTAR helped me understand what we do here more than anything I ever learned in school.”

Interns supporting the F-35 program present what they learned from the training at the end of their internships. “I was blown away by what they learned,” Tim Reeves, F-35 chief engineer, said.

Accelerating Mission Readiness

ASTAR Engineering training is already making an impact for the Northrop Grumman team. So far, the program has:

- Improved quality by identifying and correcting “overengineered” designs, saving time and reducing cost.

- Accelerated learning and helped engineers better understand the cost implications of their design choices.

- Received overwhelmingly positive feedback and has a wait list of 500+ engineers ready to enroll.

“When engineers realize their design takes longer than they imagined it would to build, they start asking better questions,” said Chrys. “Do we really need eight holes? Could we use an alternate material or process? That’s when you start seeing real savings — in time and cost.”

By re-evaluating their designs, trainees reduce steps and rework, lower costs with alternate materials and increase agility by aligning designs to time and tooling constraints.

What's Next

The long-term goal? David and Chrys predict that ASTAR Engineering will one day be part of new-hire onboarding, internship training and talent development processes.

“ASTAR Engineering is more than a program,” David said. “It’s a shift in how we build engineers — and how engineers build the future.”

Life at Northrop Grumman

Your work at Northrop Grumman makes a difference. Whether you want to design next-generation aircraft, harness digital technologies or build spacecraft that will return humanity to the moon, you’ll contribute to technology that’s transforming the world. Check out our career opportunities to see how you can help define possible.