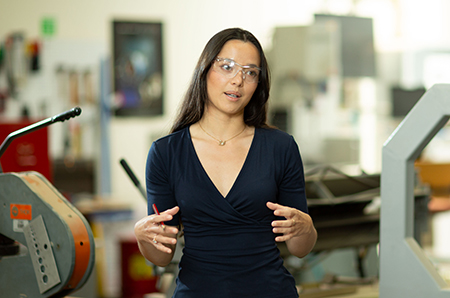

For Energetics Engineer Heather — test day — is more exciting than most.

Zooming In

By Kate Nabours and Matt McKinney

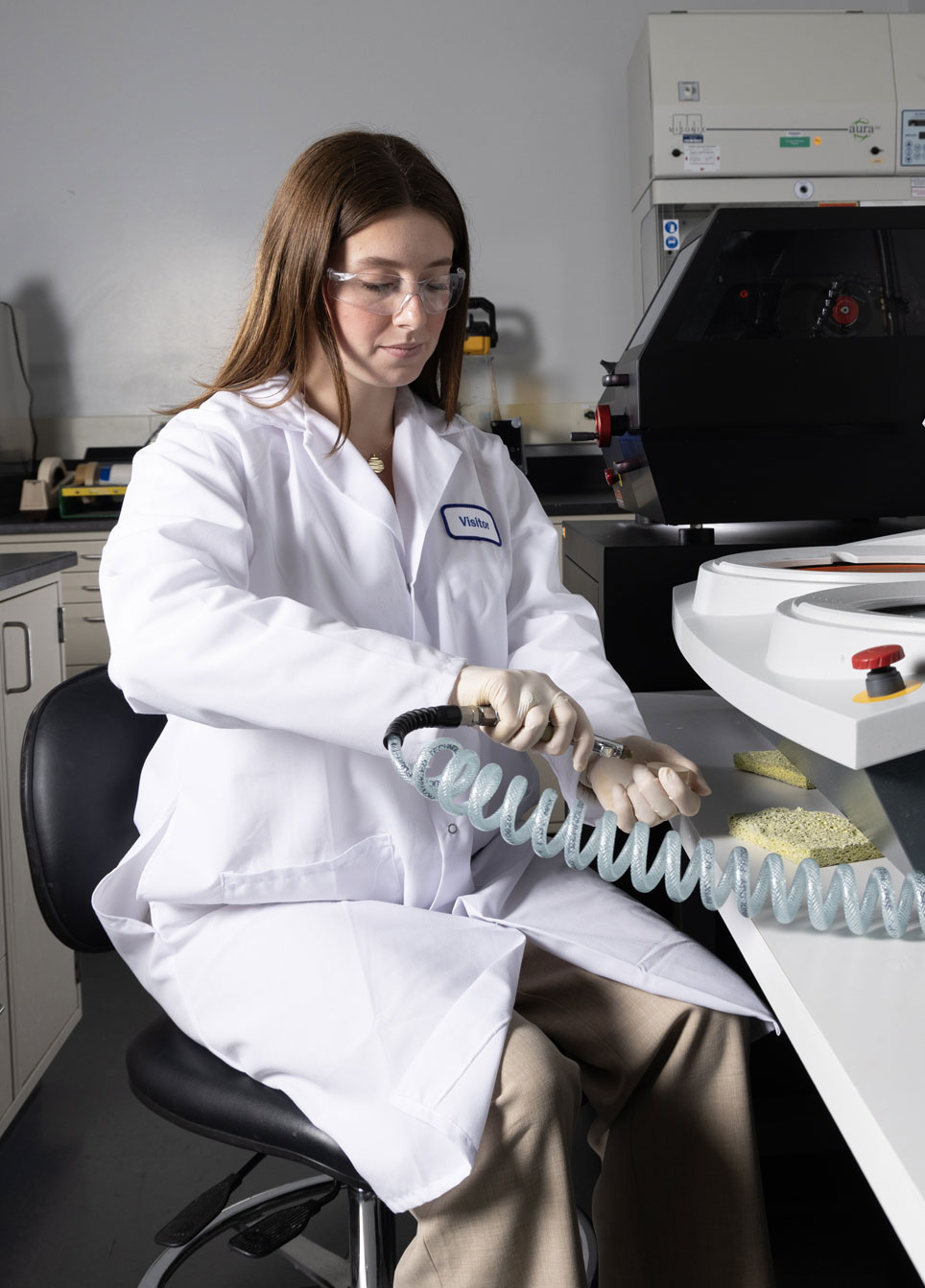

Inside Northrop Grumman’s metallography lab in Redondo Beach, California, Engineer Kate Nabours and her colleagues uncover mission-critical details that are imperceptible to most people. Harnessing ultra-powerful microscopes, the close-knit team of technicians and engineers hunts for potential flaws in the microstructures — grain-like patterns visible only when magnified — of metals, alloys and other materials used in engine components, spacecraft and other products.

Using just a sliver as a test specimen, the lab sizes up these materials, examining their microstructures to see if the material is tough enough to handle space and pushing it to its limits. Put another way: Before a spacecraft can leave Earth, Kate's team must zoom in on the granular to ensure the product’s components will perform in the extreme temperatures, solar radiation and other harsh conditions ahead.

Below is a typical workday through the eyes of Kate, who joined Northrop Grumman in 2022 after graduating from UCLA with a bachelor’s degree in chemical engineering.

6 a.m. I like to start my day with the overnight oats and cold brew I made the night before so I can head straight out the door. On my commute, I listen to upbeat music (like Harry Styles) to make my drive on the 405 highway go by fast and put me in a good mood.

7:30 a.m. By the time I arrive, the lab is already humming. Most days, we start with a brief meeting to determine which projects need our immediate attention, guided by feedback from customers. Although program-related tasks generally take priority, we also work on a variety of research and development projects.

8 a.m. With our priorities set, I head to my desk and get behind the microscope in search of any tiny problems that could cause big issues in the future. Typically, my colleagues Adam York and Will Parra have already prepared the test specimens. This is a meticulous process that involves carefully shaving off a sample from the material we are testing, sticking the sample in epoxy — a strong glue that keeps the tiny parts of materials together — and polishing the epoxied sample so that it is smooth enough to slide under the microscope lens for review.

10 a.m. I meet with customers, fellow engineers from across Northrop Grumman who rely on our lab’s data and insights to inform their design processes. For example, our team might look at a material used on the outside of satellites to make sure it can withstand the rigors of space travel. Customers are often looking to understand how to prevent potential material breakdowns or to ensure that materials meet required specifications.

11 a.m. Next, our team develops an approach for what the customer needs. Every material — from advanced alloys to specialized polymers — is different, so we are always asking each other questions and bouncing around ideas. Take additive manufacturing (also known as 3D printing) for example: A customer may come to us with dozens of different parameter sets — specific combinations of printing variables like temperature and speed — for us to test and see which combination makes the strongest parts.

Noon. Lunchtime is my moment to recharge. I often eat outdoors with a colleague, enjoying homemade favorites like ravioli with salad or a chicken burrito bowl.

1 p.m. We generally reserve the second half of the day for getting test samples microscope-ready for the next morning. We put each sample in a mold with epoxy, and since specimens can take up to 12 hours to dry, we prepare lots of them at the same time so they can cure simultaneously overnight.

4 p.m. I use late afternoon to catch up on emails and update customers on key findings from the day. My favorite part of my work is that I'm always learning. My colleagues have been such great mentors, especially as someone just starting off in my career. There's a beauty in looking closely to see what others can’t.

Life at Northrop Grumman

Your work at Northrop Grumman makes a difference. Whether you want to design next-generation aircraft, harness digital technologies or build spacecraft that will return humanity to the moon, you’ll contribute to technology that’s transforming the world. Check out our career opportunities to see how you can help define possible.