Finding a Single Source of Truth with Model-Based Systems Engineering

By Kelly McSweeney

Know a systems engineer? Then you know a communicator and a translator – from the world of engineering. Since the discipline began, systems engineers have worked on design, requirements, and interfaces to make sure every stakeholder is on the same page. But now they are operating with a hugely important change.

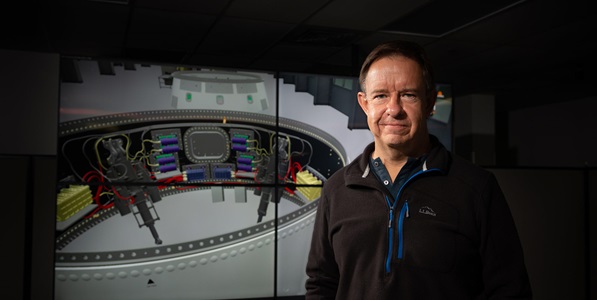

"Today we work almost entirely in a digital environment. We’re leveraging technology and tools to be even more efficient and connected than we were in the past," says Christy Haworth, Manager, Systems Engineering at Northrop Grumman.

Haworth is leading her team in the transition from traditional methods to digital engineering methods, specifically Model-Based Systems Engineering (MBSE). MBSE is transforming the way we design systems such as aircraft and space vehicles. But the transition to digital engineering didn't happen overnight; it's an ongoing process that's still happening today.

What is Model-Based Systems Engineering?

MBSE still follows the traditional principles of systems engineering, but strives to integrate a descriptive modeling tool with other digital tools used by the discipline such as circuit simulators, schematic capture, mechanical assembly drawings, thermal analysis, physics mathematical modeling and simulation, cost estimation, and more.

The descriptive modeling tool has introduced two key innovations to performing systems engineering that make MBSE an improvement over the way systems engineering was approached in the past. First, it leverages a modeling language and second it utilizes a database to serve as a repository for the objects describing the system and the relationships between them.

Move over PowerPoint, There’s an Integrated Toolset in Town

Previously, systems engineers would keep track of the system design using disparate tools such as Word documents, Excel spreadsheets, computer models, program schedules, and PowerPoint, in fact, lots and lots of PowerPoint. Diagrams were created in PowerPoint to describe various aspects of the system design, often incorporating information from other documents, using symbology chosen by the author in an attempt to best communicate their thoughts.

Often an engineer would have to describe the meaning of a diagram in PowerPoint to their audience and hope it was conveyed and interpreted as intended. Additionally, with no real connection to the other documents information from another source could potentially be out of date.

A modeling language improves on this by introducing a “vocabulary” for describing systems (ie. – a standard symbology to describe different aspects of the system). Now engineers need only learn the modeling language and develop diagrams in the descriptive modeling tool to communicate the system design. Stakeholders that also understand the modeling language immediately know how to interpret the diagrams.

“Prior to MBSE, information regarding system design was held in multiple unconnected sources," says Haworth. "We had to rely on the human interface and analysis to connect the information and look for any gaps that needed resolution. With MBSE we limit the number of places information about the system is produced and stored, thereby reducing the effort required to resolve discrepancies and increasing the affectivity of design analysis."

Because the descriptive modeling tool is a database, the symbols on the diagrams also hold relevant details about the system object they represent and, most importantly, enter into relationships with other system objects (stored in the database). With all the information describing the system design stored in the database, the modeling tool is referred to as “the single source of truth” for the system design.

Reaping Benefits from a Single Source of Truth

MBSE strives to bring all these sources of information together seamlessly. All stakeholders work in the same database, the single source of truth (SSOT). Systems engineers can use the database rather than separate artifacts to eliminate inconsistencies and/or repetition that can result from having information stored in multiple unconnected resources.

Using a single source of truth prevents miscommunication and discrepancies that required additional time consuming analysis to resolve in the past. With MBSE, instead of producing a patchwork of documentation in semi-isolation, engineers leverage a modeling tool using a standard language to populate a database with information about the system design. The documentation produced from the modeling tool on demand is always up to date and always consistent.

The Heart of Systems Engineering: Communication

Previously, if one aspect of the system was changed during the design process, it was up to engineers to manually trace the impacts throughout the entire design. Now, with MBSE there is built-in traceability. Even the slightest tweak to a design immediately trickles through the entire database so that any consequences of that change are immediately visible.

"MBSE dynamically connects us to different people and the technical information they generate across our programs and our company more closely and more collaboratively," says Haworth. She adds, "It enhances communication, which, in my opinion, is the true heart of systems engineering."

MBSE facilitates communicating consistently and in a way that all people involved can understand. While consumer software such as Word documents have freedom and flexibility, digital engineering tools used in MBSE provide a rigorous set of rules to follow for representing different aspects of a system design. "We follow a consistent approach using a standard modeling language to build a database of information that can be understood by all stakeholders," she says, noting that both internal teams and the customer will understand the result.

The Digital Ecosystem Will Soon Be Second Nature

The transformation to digital engineering, including MBSE, is happening step by step. The evolution goes beyond just MBSE and will eventually effect areas outside the traditional areas of systems engineering and engineering in general.

"We're taking steps every day to connect these digital environments into a cohesive digital ecosystem," Haworth explains “we are considering how engineering, scheduling, pricing, and other factors that all support the delivery of a product fit into this digital construct.”

When multiple digital tools are connected, those involved in the development of products will be able to pivot more quickly to support customers’ needs regardless if the products are still in design or have already been deployed for many years. When all aspects of the design are in one place, Northrop Grumman can respond quickly to the needs of customers. For example, if a vehicle was originally designed to withstand a desert environment but later needs to operate in a swampy environment, engineers can quickly trace the impacts through the integrated digital tools to determine what kind of changes the vehicle will need to accommodate the new condition.

“As we continue to leverage our increasingly connected digital tools, the fact that they are intelligently integrated will evolve from being the desired state to the fully expected reality,” says Haworth. She continues, “Much like how technology has become second nature in our personal lives, there will come a time when we can’t imagine work outside of the digital ecosystem.”

More Innovation Stories

Read all stories about advanced technology and innovation >>