The End Game: Extended Reality (XR) Transforms Platform Sustainment

By Scott Gourley

While once the stuff of science fiction, virtual and augmented reality are now accessible to just about everyone. Even our smartphones are making augmented reality mainstream, with applications in practically every environment, from entertainment, to hospitality and travel, to health care, theme parks, automotive and more, this technology is now touching almost every aspect of our daily lives, immersing us in new environments and helping us see and interact with our world in entirely new ways.

This exciting new technology –and how it can be used - is rapidly evolving, and expanding that the new advancements are outpacing the terminology used to describe them. In these cases, terms and acronyms once pegged to a particular platform type or capability are being quickly modified and re-modified to reflect a broader use across multiple environments.

A classic example is the rapid evolution of how information is being presented, accessed and employed in manufacturing, maintenance, and system sustainment environments, where virtual reality (VR) and augmented reality (AR) technologies have blended with mixed reality (MR) capabilities to create what can only be described as a new, extended reality (XR).

How Sustainment and Modernization Experts Incorporate Digital Transformation

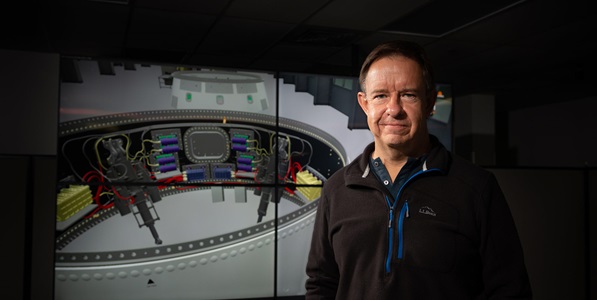

And at Northrop Grumman, a team of experts is at the forefront of how XR is being used to improve program performance, efficiency and affordability in delivering platform sustainment and modernization – and more.

"Digital capabilities are transforming aircraft sustainment," said Kenn Todorov, sector vice president, global sustainment and modernization, Northrop Grumman. “XR really encompasses all the elements of VR, AR, MR as well as physical reality and is changing the way we perceive, operate and deliver capability in the real world, helping us prepare for and experience a variety of situations that you can't safely replicate in the real world.”

Protecting Extended Reality Experiences with Cybersecurity

At the crux of the company's XR work is wearable technology – enhanced versions of those heads-up displays introduced for everyday gaming - that is transforming the way the team works and trains. This technology enables subject matter experts, maintainers and others to access, see and share data or instructions from almost anywhere in the world.

"We realized early that XR could be implemented and expanded to be used across lifecycle logistics for a variety of platforms and systems, from initial training to the operational environment," observed Northrop Grumman program manager and principal investigator for XR technologies, Johnny Rice.

Rice elaborated on applications in the training environment, offering the example of performance analytics, where XR not only provides information to the student but also tracks and measures levels of proficiency and even has potential to adjust how some maintenance is performed.

While acknowledging the expanded efficiency of XR technologies, he also was quick to emphasize the criticality of cybersecurity protections into the system architecture.

"We listened to our customers," he said. "And we saw this as an opportunity to begin investing into cybersecurity and the requirements necessary for someone to put on a wearable headset, for example, and operate in demanding cyber secure environments."

As a result, company field service representatives and engineers are now using these wearable, cyber secure-compliant, Northrop Grumman-approved devices for customers in both US and international environments.

XR: A Vision of the Future

But the team isn’t stopping there.

“Since then, we have continued to implement and mature XR technology for existing systems while also looking forward to future applications and environments,” said Rice. "If we tie XR to a particular technology or a particular ecosystem, such as aircraft maintenance, we don't do justice to the full body of work that has taken place over the course of the last few years in our research and development."

System architect Phillip Hammer expanded on that.

"We didn't invent the wearables," he said. "Instead, we took commercially available devices and advancing technologies and combined it with our deep understanding of sustainment needs in training and delivering information, our understanding of what exists in digital threads and our knowledge of how to pull that information and turn it into the modality that's supported by these wearable devices, where an early vision of commercial market applications has quickly broadened to new arenas."

In optimizing those new arenas, Hammar pointed to another complementary capability: Northrop Grumman's understanding of how the information needs to move and how that might be impacted by deployment to various types of challenging environments.

"Getting to an end state where the warfighter is able to use this in a foxhole or other austere tactical environment means that the wearable technology needs to be really tough, reliable and proven," echoed lead software systems engineer Kenneth Wiles. "Fortunately, we are getting there quickly through advances in technology. If you look at some of the industry and government investments being made today, you will find confirmation that XR technologies are not only here to stay but that the related devices are setting the stage for the next revolution in computing."

"Ten years from now, people will look back and wonder how they ever did their jobs without having this device on their head," he concluded. "It's really going to become a ubiquitous technological presence in terms of sustainment, manufacturing and anything else that involves physical awareness of things. Quite simply, these XR platforms will provide the necessary vision and insight into what needs to be done."

More Innovation Stories

Read all stories about advanced technology and innovation >>